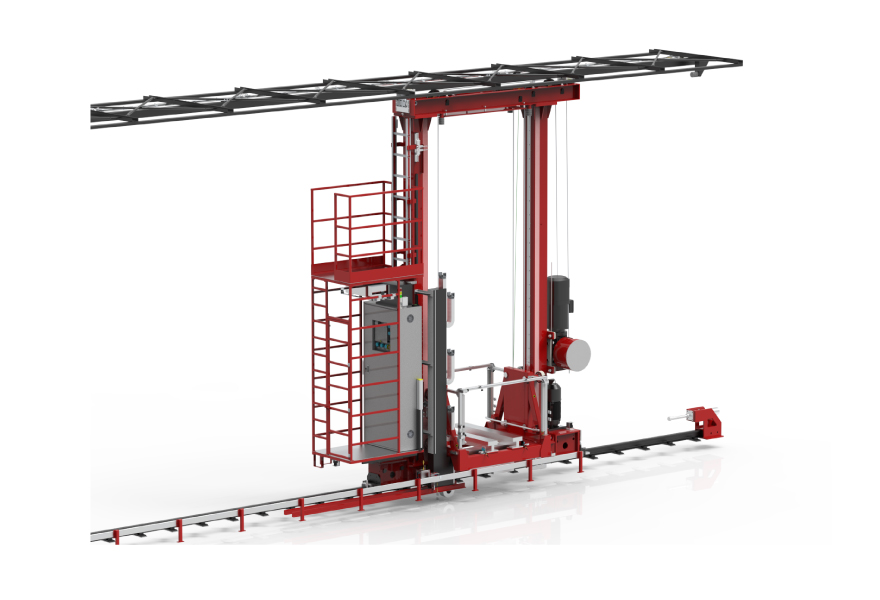

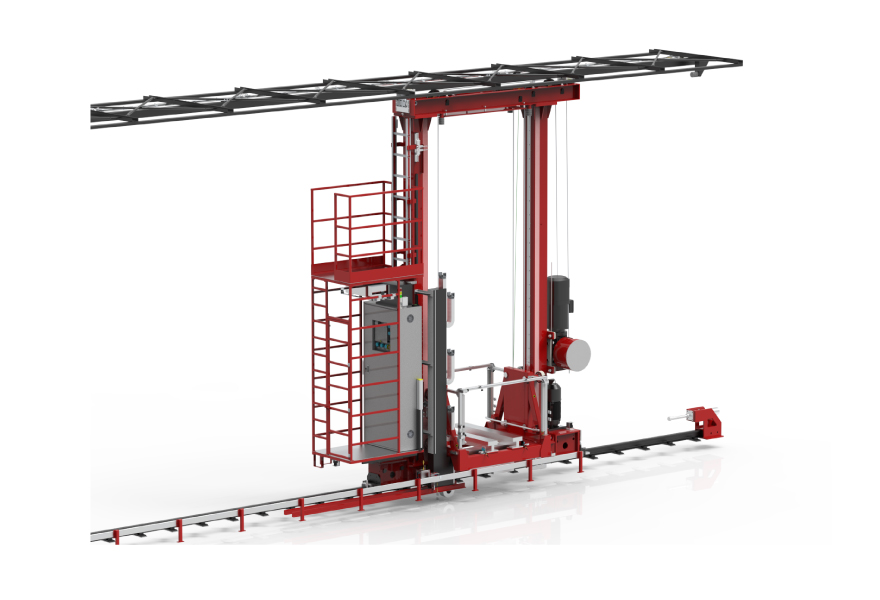

Stacker cranes are overhead crane systems that utilize non-hoist handling devices used in warehouses to move, store, and retrieve loads automatically.

These cranes operate on rails mounted to the floor and are guided by an upper rail attached to the storage racks.

Stacker cranes are widely used in commercial and industrial warehouses. The main components also include guide rails, a power supply system, and a data transmission system (WCS/WMS).

However, selecting the right stacker crane for your specific needs can be challenging.

Types of Stacker Cranes

The market offers a variety of stacker cranes tailored to different warehouse requirements. These variations primarily depend on the types of loads handled—such as pallets or boxes—and the structural design of the crane itself.

1. Single-Mast Stacker Cranes

Single-mast stacker cranes are designed for both pallets and boxes. These cranes are typically used in warehouses with lighter load requirements and are renowned for their efficiency and agility. Single-mast cranes for pallets come in several models, each capable of reaching different heights and handling varying load capacities.

Key Features of Single-Mast Stacker Cranes for Pallets:

-

Height Range: Up to 148 feet for single-deep configurations.

- Load Capacity: Between 1.1 to 1.65 tons depending on the model.

- Operational Temperature: Can function in temperatures as low as -22 °F.

- Applications: Suitable for lighter load operations where high throughput is essential.

Key Features of Single-Mast Stacker Cranes for Boxes:

-

Height Range: Up to 39 feet.

- Load Capacity: Up to 220 pounds.

- Speed: Maximum travel speed of up to 656 feet per minute.

- Applications: Ideal for high-productivity environments requiring frequent handling of lightweight goods.

2. Twin-Mast Stacker Cranes

Twin-mast stacker cranes are designed to handle heavier loads and are structurally more robust than their single-mast counterparts. These cranes are suitable for operations that demand high storage density and can handle pallets weighing up to 1.65 tons

Key Features of Twin-Mast Stacker Cranes:

-

Height Range: Up to 148 feet for double-deep configurations.

- Load Capacity: Consistent load handling up to 1.65 tons.

- Operational Temperature: Also capable of functioning in temperatures as low as -22 °F.

- Applications: Suitable for heavy load operations and environments requiring high storage density.

Twin-mast cranes can also be equipped with pallet shuttles, which enhance their ability to store and retrieve pallets in high-density environments. This configuration is especially useful in automated cold storage facilities, where maximizing storage space while minimizing energy consumption is critical.

3. Trilateral Stacker Cranes

Trilateral stacker cranes offer a unique advantage over single-mast and twin-mast cranes due to their ability to retrieve and deposit pallets from three different positions—front and either side—using a rotating head. This feature makes them particularly suitable for warehouses that have existing manual trilateral turret trucks and are looking to automate without significant structural changes.

Key Features of Trilateral Stacker Cranes:

-

Flexibility: Can operate without an upper guide rail, allowing for easier integration into existing facilities.

- Applications: Ideal for retrofitting existing warehouse setups without significant modifications.

Extraction Systems: The Key to Performance

The extraction system is a critical component of a stacker crane, influencing its performance and storage capacity. Common options include:

·Single-deep system: Ideal for high throughput and agility.

·Double-deep system: Provides a balance between agility and storage capacity.

·Triple- or quadruple-deep system: Offers maximum storage capacity but sacrifices agility.

·Motorized roller conveyor platform: Suitable for pallet flow racks and continuous movements.

Choosing the Right Stacker Crane

Selecting the appropriate stacker crane for a warehouse involves understanding several factors such as the type and weight of the loads, the desired storage density, and the required operational speed.

It's essential to assess these needs carefully to choose a stacker crane that offers the most functional and cost-effective solution.

1. Load Type and Capacity: Determine whether your warehouse primarily handles pallets, boxes, or a mix of both. This will guide you toward selecting either a single-mast, twin-mast, or trilateral stacker crane.

2. Storage Depth: Consider whether a single-depth, double-depth, or multi-depth storage system is most appropriate for your needs. Single-depth systems prioritize speed and flexibility, while double-depth and beyond systems offer increased storage capacity at the expense of speed.

3. Operational Environment: The temperature range within which the stacker crane will operate is another crucial factor. Stacker cranes designed for cold storage environments require specific modifications to function effectively at low temperatures.

Troubleshooting in ASRS Stacker Cranes

Automated Storage and Retrieval Systems (ASRS) involving stacker cranes are highly reliable but not without occasional issues.

Take a glimpse at common problems and their solutions can help maintain optimal performance:

- Loose Rope Issues: A common problem in stacker cranes is the loosening of ropes, which can lead to operational inefficiencies or even accidents. Regular maintenance checks should include tightening ropes and ensuring that all components are securely fastened.

- Misalignment: Over time, rails can become misaligned, leading to increased wear and tear on the stacker crane. Regular inspections and adjustments can prevent this issue from escalating into a major problem.

- Software Malfunctions: The warehouse control system (WCS) that manages the stacker crane's operations may sometimes face software glitches. Ensuring regular software updates and system checks can minimize downtime caused by such issues.

Automated Stacker Cranes are helpful in improving productivity and increasing storage capacity for most industrial and commercial warehouses.

However certain layouts and models of stacker cranes might be prioritized for specific functionalities. it’s best to consult stacker crane manufacturer.

Don’t hesitate to contact us now, our team of experts is ready to find the best fit for your warehouse.

Network Supported

Network Supported