Call Us :8615298359310

Call Us :8615298359310

Pallet racks come along with multiple types of parts/accessories to ensure their functions are properly tailored to storage needs. Now from this article, we shall sketch out the main components of pallet racking and their features.

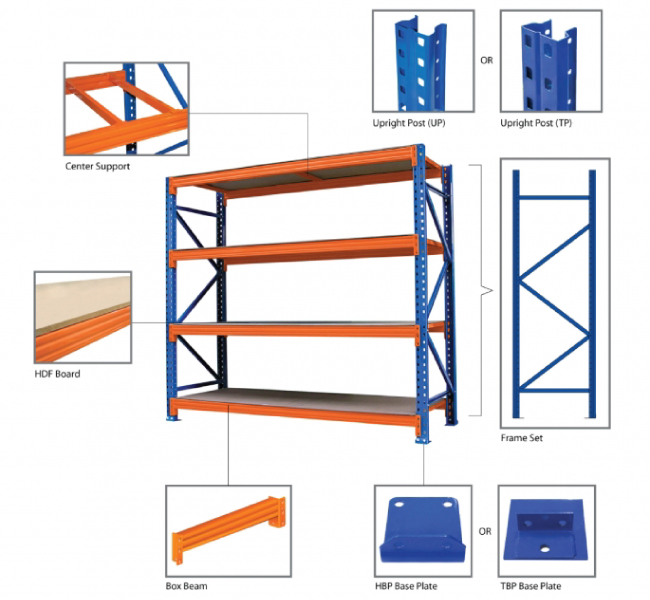

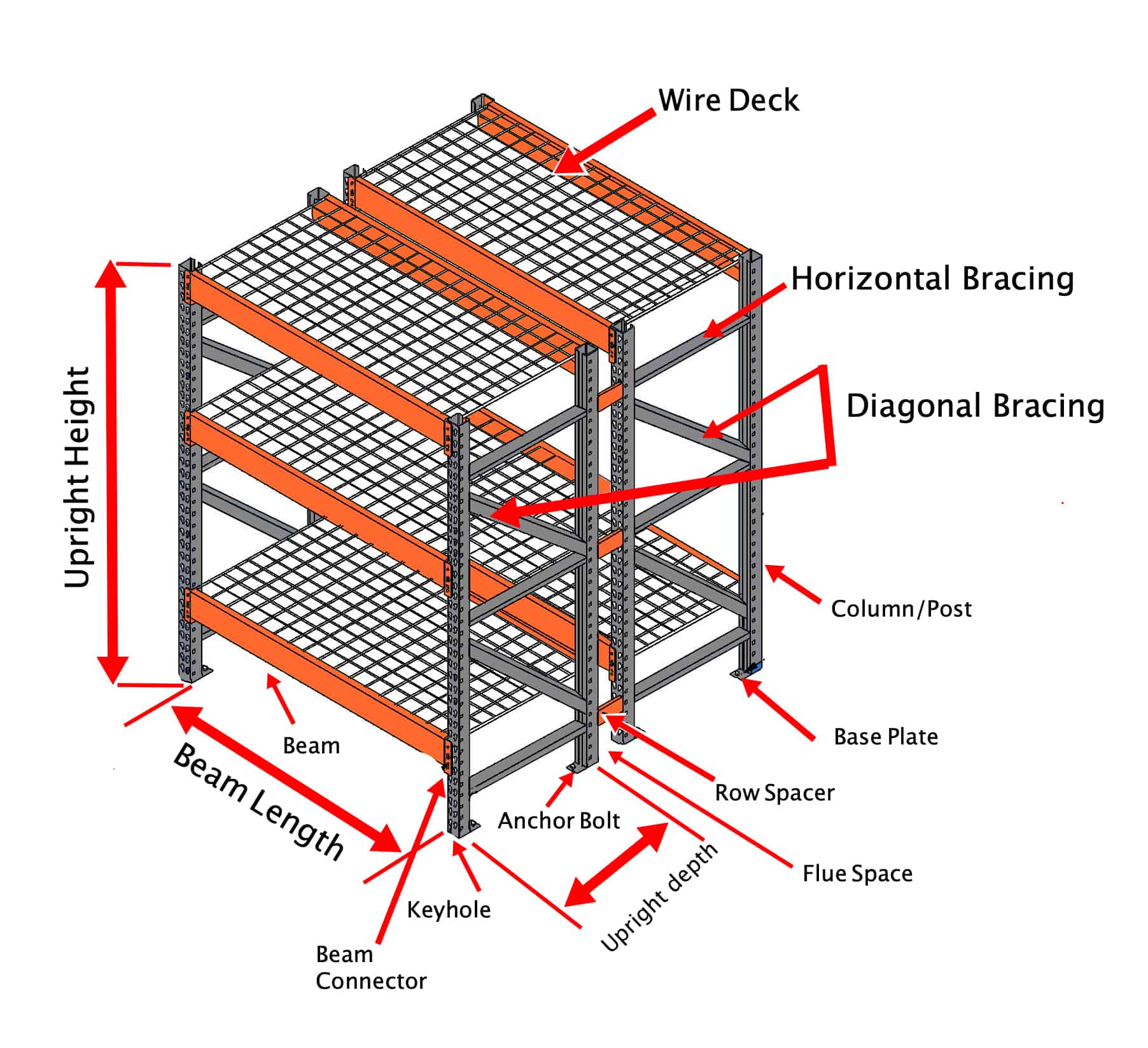

Pallet racks are composed of various components that ensure the secure storage of goods. The fundamental parts include posts, diagonal struts, frames, beams, and shelf panels. Each component plays a critical role in maintaining the rack's stability and load-bearing capacity.

Posts form the vertical support of the racking system. These metal parts come with footplates that anchor the structure to the warehouse floor. Frames, constructed from posts and diagonal struts, provide the necessary vertical stability. The diagonal struts reinforce the load capacity, ensuring the structure can withstand heavy loads without compromising safety.

Beams are horizontal metal profiles attached to the frames. They support the pallets and shelf panels where goods are stored. Shelf panels, which can be grated, wooden, or galvanized metal, rest on these beams, offering a versatile platform for various types of merchandise.

Crossbars are critical for load stability, preventing pallets from falling off the racks. They are especially important for operations involving frequent pallet movement. Bracing, or cross bracing, consists of metal profiles affixed to the beams to enhance the rack's load capacity and stability, crucial for heavy-duty applications.

Shims are used to level the pallet racks on uneven flooring, ensuring the structure remains stable. Locking devices, welded to the endplates, secure the beams to the posts, preventing accidental disengagement. This feature is vital for maintaining the integrity of the storage system under dynamic loading conditions.

Row spacers connect different pallet rack modules, ensuring a cohesive and stable structure. Various shelving panels are available, each designed for specific storage needs. Galvanized shelving is ideal for heavy loads, metal shelving is suitable for order picking, wire mesh shelving allows water circulation for fire safety, and chipboard shelving supports diverse load types.

Safety accessories are essential for protecting the goods, racking structure, and warehouse personnel. Common accessories include protectors, fall protection netting, adapters for irregular loads, and signage accessories. These components play a significant role in preventing accidents and enhancing operational efficiency.

Protectors are vital for safeguarding the racking structure from impacts. End aisle protectors, post and frame protectors, corner protectors, and post reinforcers all contribute to maintaining the rack's integrity. Fall protection netting, installed at the back of the racking, prevents goods from accidentally falling, protecting both the inventory and the workers.

Adapters like container supports, drum beds, and drum cradles are designed for irregular loads. They ensure these unique items are securely stored, reducing the risk of accidents. Signage accessories, including safe load warning notices, aisle signs, and sign holders, improve safety by clearly identifying load capacities and storage locations.

Warehouse workers must also be aware of other critical safety measures not always highlighted. Regular inspections for wear and tear, prompt replacement of damaged components, and adherence to load limits are fundamental practices. Additionally, proper training in using equipment like forklifts and understanding the racking system's layout can prevent accidents and enhance efficiency.

If you're still struggling with which type of pallet racking system will fit your warehouse best, you're not alone. just contact us now thus our team of experts can advise you on the best possible warehouse storage solution.

Copyright © 2024 Jiangsu VISON Logistics Technology Co., Ltd. All Rights Reserved.  Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy