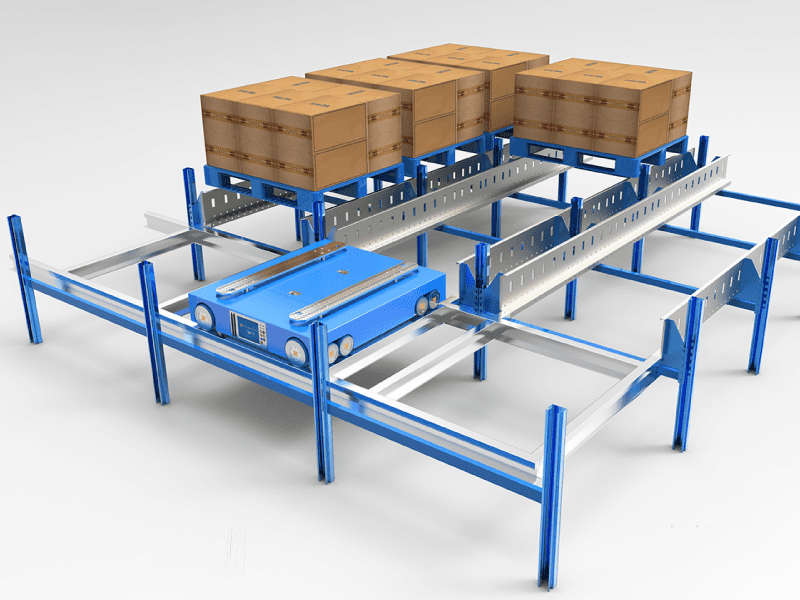

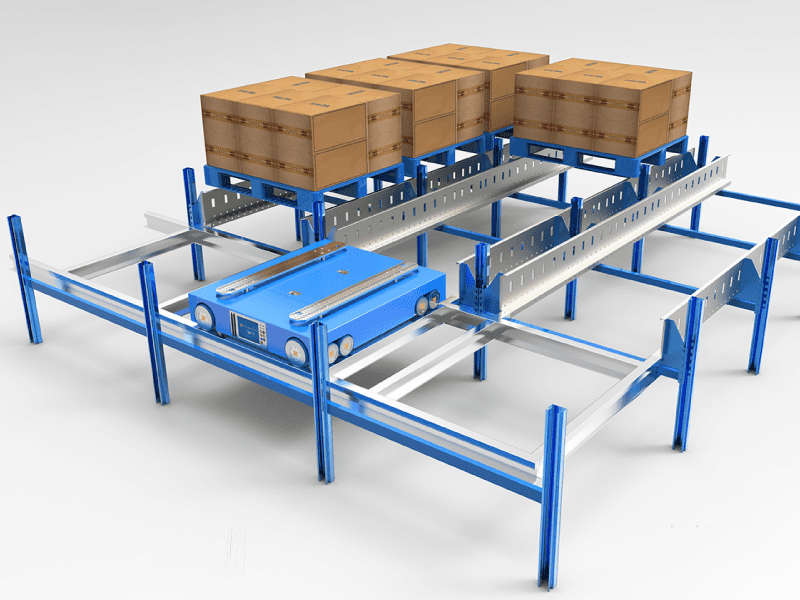

For efficient pallet storage in warehouses that those have high rotation needs, shuttle racking could be the unsung hero to maximize efficient space utilization.

What is Shuttle Racking?

Shuttle racking integrates automated carts, known as shuttles, with high-density pallet racking to create a pallet shuttle racking system. These systems eliminate the need for forklifts to navigate narrow aisles, instead relying on remote-controlled shuttles to move pallets to and from storage locations.

Inventory Management Method: FIFO and LIFO

Shuttle racking systems adapt to diverse inventory management needs through two primary configurations:

- First-In-First-Out (FIFO): Ideal for perishable goods or products with expiration dates, FIFO systems ensure older stock is retrieved first. Pallets enter from one end of the lane and exit from the opposite end, maintaining a consistent flow of inventory.

- Last-In-First-Out (LIFO): Suited for non-perishable items or high-volume storage, LIFO systems allow pallets to be loaded and unloaded from the same end of the lane. This configuration maximizes storage density in single-access warehouses.

The choice between FIFO and LIFO depends on factors such as product characteristics, warehouse layout, and inventory turnover rates.

Key Advantages of Shuttle Racking

Implementing shuttle racking yields numerous benefits for warehouses:

- Space Optimization: Eliminating the need for the aisle and enabling deeper storage lanes, shuttle systems can increase storage capacity by up to 50% compared to traditional racking

- Enhanced Safety: Automated shuttles minimize the risk of accidents associated with manual forklift operations in narrow aisles.

- Improved Efficiency: Shuttle carts can retrieve pallets in seconds, significantly reducing picking times and boosting overall productivity.

- Scalability: Modular designs allow for easy expansion as storage needs grow.

- Energy Efficiency: Shuttle systems often consume less energy than conventional forklift-based operations, contributing to sustainability goals.

Types of Shuttle Carts

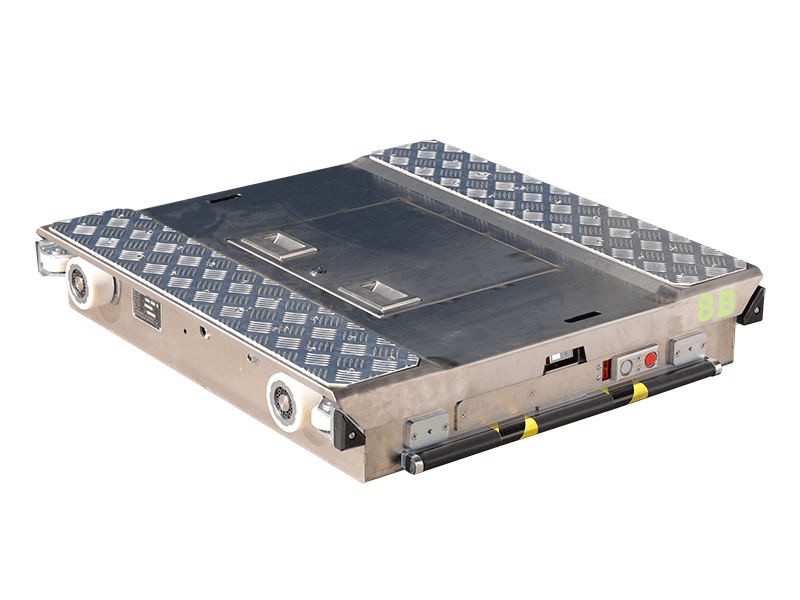

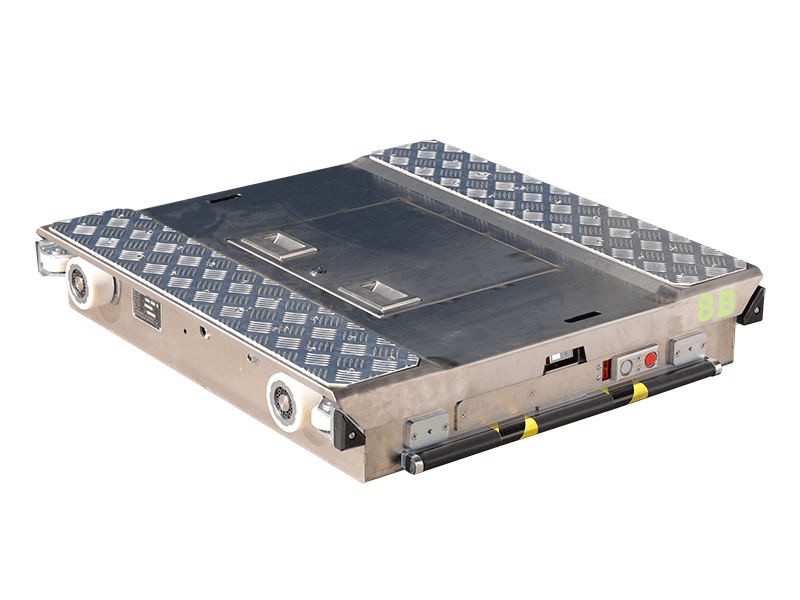

The heart of any shuttle racking system lies in its automated shuttle carts. Several types of shuttle carts cater to different warehouse requirements:

Single-Level Shuttle Carts

Single-level shuttles operate on a single rack level, moving horizontally to transport pallets within a lane. These carts excel in scenarios where rapid access to a specific SKU is crucial.

Features:

- Compact design for navigating narrow aisles

- High-speed operation for quick pallet retrieval

- Battery-powered with extended run times

Applications:

- Fast-moving consumer goods (FMCG) distribution centers

- E-commerce fulfillment operations

- Cold storage facilities

Multi-Level Shuttle Carts

Multi-level shuttles add vertical mobility to the equation, capable of servicing multiple rack levels without human intervention.

Capabilities:

- Vertical and horizontal movement within the racking structure

- Advanced sensors for precise positioning

- Increased storage density by utilizing vertical space

Use Cases:

-

Automotive parts warehouses

- Pharmaceutical distribution centers

- High-bay storage facilities

Deep-Lane Shuttle Systems

Deep-lane shuttles specialize in maximizing storage density by accessing pallets stored in several positions deep within a lane.

Key Features:

- Extended reach for accessing pallets up to 50 meters deep

- Robust construction for heavy-duty applications

- Integrated inventory management systems

Applications:

- Bulk storage of homogeneous products

- Seasonal inventory management

- Manufacturing buffer storage

Selecting the Optimal Shuttle Cart for Your Warehouse

Choosing the right shuttle cart depends on several factors:

- Storage Density Requirements: Deep-lane systems offer maximum density, while single-level shuttles provide faster access to diverse SKUs.

- Inventory Turnover: High-turnover environments benefit from faster single-level or multi-level shuttles.

- Product Characteristics: Consider weight, dimensions, and fragility when selecting shuttle capacity.

- Warehouse Layout: Existing structures may influence the choice between different shuttle types.

- Budget Constraints: While all shuttle systems require significant upfront investment, costs vary based on complexity and scale.

Implementation Considerations and ROI

Implementing a shuttle racking system requires careful planning:

1.Conduct a thorough analysis of current and projected storage needs.

2.Assess the compatibility of existing infrastructure with shuttle technology.

3.Train staff on system operation and maintenance procedures.

4.Develop contingency plans for potential system downtime.

While the initial investment in shuttle racking can be substantial, the long-term benefits often justify the cost. Warehouses typically see returns through:

- Reduced labor costs

- Increased storage capacity without facility expansion

- Improved order fulfillment rates

- Enhanced inventory accuracy

- Lower energy consumption

Many businesses report ROI periods of 2-5 years, depending on the scale of implementation and operational improvements achieved.

Future Trends in Shuttle Racking Technology

As warehouse automation continues to evolve, several trends are shaping the future of shuttle racking:

- AI-Driven Optimization: Machine learning algorithms will enhance shuttle routing and inventory placement for maximum efficiency.

- IoT Integration: Sensors and connected devices will provide real-time data on system performance and inventory levels.

- Autonomous Vehicles: Self-driving shuttles may eliminate the need for remote control, further reducing human intervention.

- Sustainable Design: Future shuttle systems will likely incorporate eco-friendly materials and energy-efficient propulsion methods.

Shuttle racking represents a significant leap forward in warehouse automation, but it can be a hard choice since so many factors concern the warehouse operation.

If you’re still confused about which type of storage solution fits you best, don’t hesitate to contact us now, our team of experts is ready to sort out what fits you best.

Network Supported

Network Supported