Powers the Supply Chain for Ningde Times with Automated Warehouse Solutions

Ningde Times, a leading solar power manufacturer, has embarked on an ambitious project to construct an integrated smart factory that combines intelligent production with cutting-edge storage solutions. The highlight of this new facility is a highly advanced automated warehouse featuring a 30,000-square-meter high-bay racking system, designed to handle the rapid growth of solar product manufacturing and logistics. This warehouse is built to support 20 aisles, 220 columns, and 6 levels, with a total of 53,000 storage slots, all optimized for efficient and automated storage retrieval.

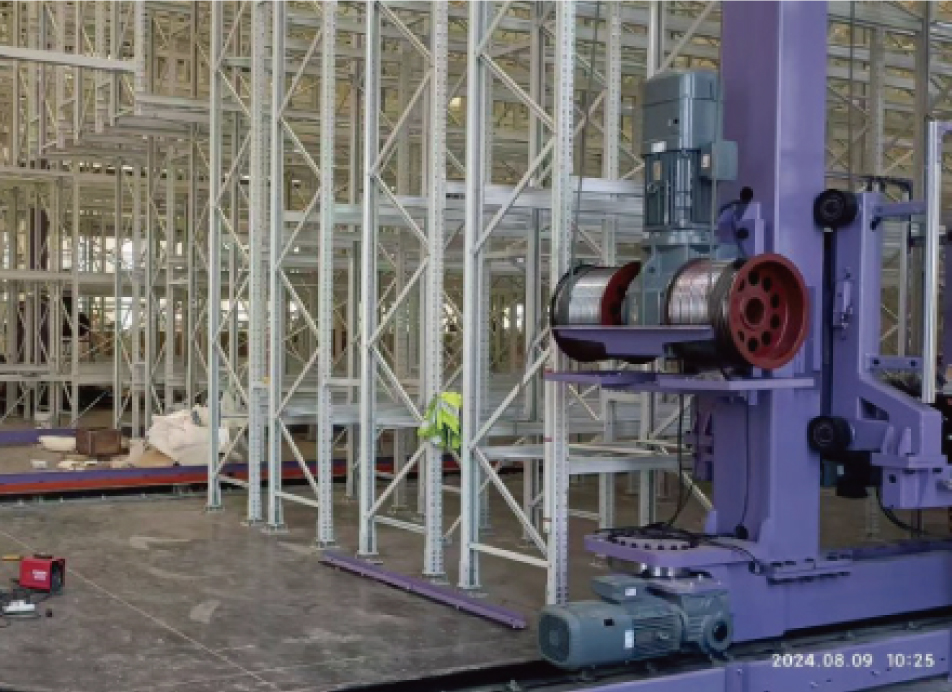

At the core of this system are 20 rail-guided stackers, each operating along a 220-meter-long track. These stackers are equipped with vertical lift machines that use wire ropes to move cargo trays up and down, allowing the efficient retrieval and storage of photovoltaic products. The process is designed to be fully automated, with the stackers utilizing high-precision barcode scanners and cameras to track inventory in real-time. This intelligent system not only improves storage density but also boosts operational efficiency.

One of the main challenges faced during the construction of this state-of-the-art automated warehouse was ensuring the reliable communication between the stackers and the central control system. Given the high volume of goods being handled every day, maintaining stable and secure wireless communication is critical to the smooth operation of the system. The warehouse’s dense steel structure and closely spaced stackers posed potential obstacles for network connectivity, leading to concerns about signal interference and network degradation.

Tailored Solution by Vison Racking

To address these challenges, Vison Racking, a provider of advanced racking and storage solutions, designed a custom solution specifically for this project. Each of the 20 rail-guided stackers is equipped with two high-definition cameras and barcode scanners, while 40 specialized wireless devices are strategically deployed throughout the warehouse. These devices are installed at high locations, such as the end walls of each aisle, ensuring that real-time data can be transmitted seamlessly from the stackers to the control system.

The wireless devices provide continuous monitoring of the stackers’ positions, speeds, and movements, while also transmitting live video feeds and barcode scan data. This enables the central control system to ensure that the stackers are operating as planned and that goods are being retrieved and stored accurately. The system’s high-speed communication network guarantees that all information is transmitted without delays, facilitating smooth order fulfillment and inventory management.

Key Benefits of the Solution

Vison Racking’s solution stands out for its optimization of wireless communications. By leveraging Time Division Multiple Access (TDMA) technology and directional antennas, Vison Racking was able to significantly enhance spectral efficiency and reduce communication delays. The deployment of the wireless devices was carefully planned to avoid interference, with each device assigned a unique frequency to ensure optimal performance. The result is a robust and stable wireless network that supports the high-density, high-speed needs of Ningde Times’ automated warehouse.

Through careful calibration and testing, the wireless system was fine-tuned to ensure maximum data transmission quality. This level of precision guarantees that Ningde Times’ factory will continue to run smoothly, with increased efficiency in inventory management, order fulfillment, and overall warehouse operation.

With this innovative solution, Ningde Times is poised to redefine the future of smart manufacturing and logistics, setting a new benchmark for the solar energy industry.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information