Call Us :8615298359310

Call Us :8615298359310

Among the myriad storage solutions available, drive-in racking and drive-through racking stand out as desirable options for maximizing storage density.

This comprehensive guide vets the nuances of these systems, highlighting their similarities, differences, and optimal applications.

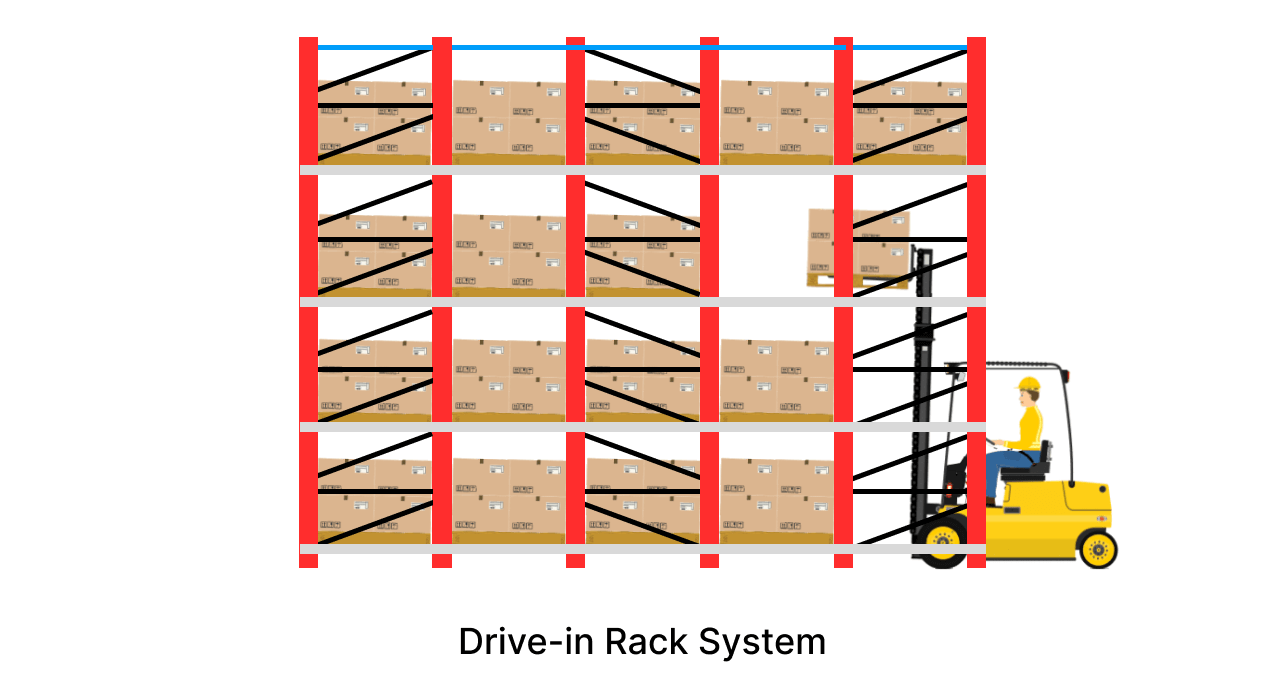

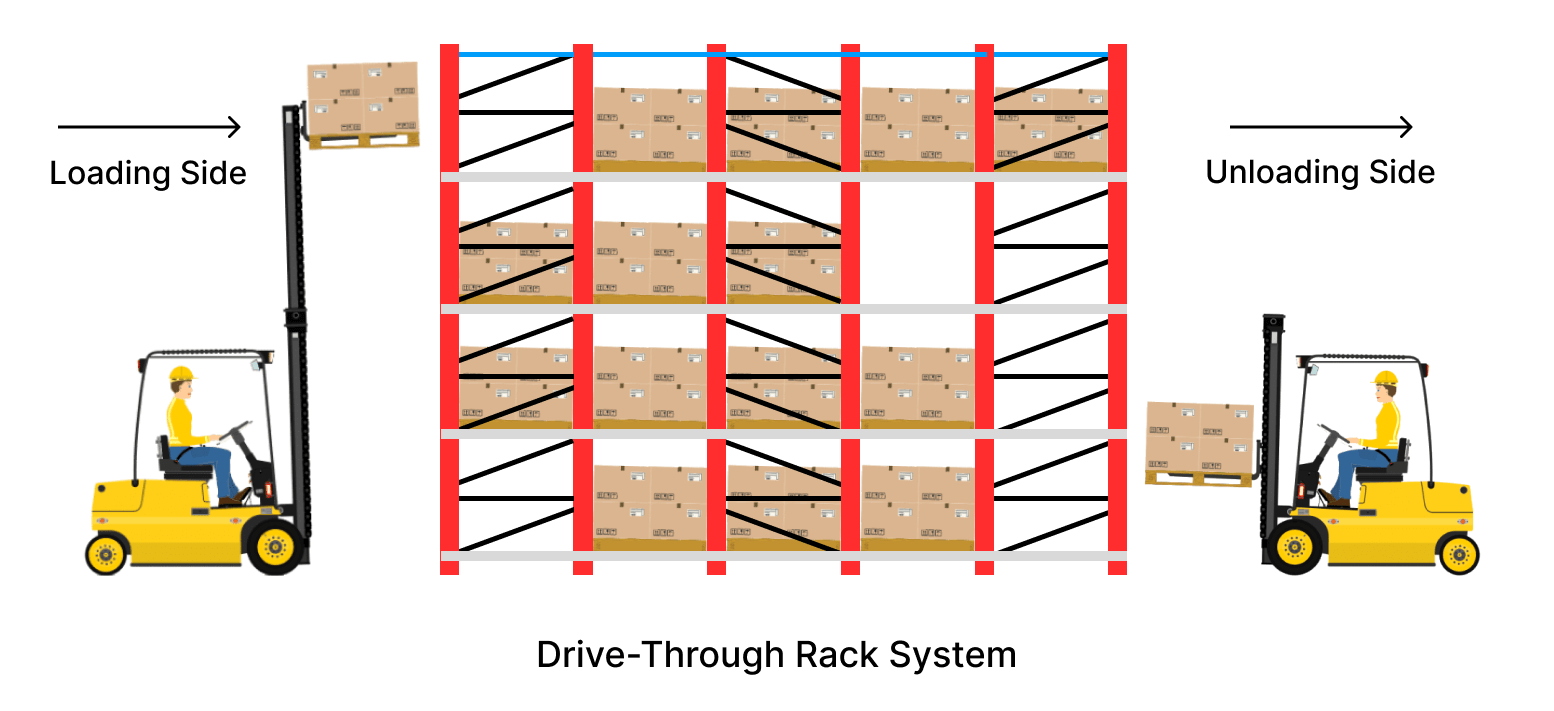

Both Drive-in and Drive-through racking systems fall under the umbrella of compact storage solutions. They share a fundamental design principle: forklift trucks enter the racking structure directly to load and unload pallets, eliminating the need for multiple aisles between rows.

Key features include:

While these systems share numerous similarities, their operational methodologies and ideal applications differ significantly.

Before examining their distinctions, it's essential to recognize the common ground between Drive-in and Drive-through racking:

1. Structural design: Both systems utilize a robust framework that allows forklifts to maneuver within the racking itself.

2. Space optimization: these systems significantly increase storage density compared to conventional racking by limiting aisle space.

3. Inventory control: Dedicating lanes to specific product references enhances stock management and organization.

4. Temperature-controlled storage: The compact nature of these systems makes them ideal for cold storage applications, reducing the total volume requiring temperature control.

Diverging Paths: LIFO vs FIFO Inventory Management

The primary distinction between Drive-in and Drive-through racking lies in their inventory management methodologies:

This fundamental difference in operation dictates the suitability of each system for various industries and product types.

While the core concepts remain similar, several operational aspects differentiate these systems:

o Drive-in: Single entry/exit point

o Drive-through: Separate loading and unloading access

o Drive-in: Reversing required for pallet retrieval

o Drive-through: Continuous forward movement possible

o Drive-in: Generally limited by forklift reach

o Drive-through: Can accommodate longer lanes due to pass-through design

o Drive-in: Limited, best for non-perishable goods

o Drive-through: Excellent, ideal for perishable items

The choice between Drive-in and Drive-through racking can significantly impact warehouse layout and space utilization:

1. Product rotation is less critical

2. Storage density takes precedence over accessibility

3. Inventory consists of non-perishable or slow-moving items

1. Strict stock rotation and freshness management

2. High-volume throughput of perishable goods

3. Compliance with first-in-first-out inventory practices

This system is particularly valuable for:

When deciding between drive-in and drive-through racking, warehouse managers must weigh several factors:

o Shelf life

o Rotation requirements

o Volume and variety of SKUs

o Storage density vs. accessibility

o Throughput speed

o Stock management practices

o Available floor space

o Ceiling height

o Loading dock configuration

o Anticipated growth in inventory volume

o Potential changes in product mix

o Forklift operator skill requirements

o Ease of rack inspection and repair

The choice between drive-in racking and drive-through racking hinges on a nuanced understanding of product characteristics, operational requirements, and long-term business objectives.

Drive-in racking provides unparalleled storage density for non-perishable goods and slower-moving inventory. In contrast, drive-through racking ensures optimal stock rotation for perishable items and high-throughput operations.

Are you still leveraging the strengths of either drive-in or drive-through racking to create a warehouse, you’re not alone. Don’t hesitate to contact us, our team of experts will advise you on the best storage solution for your warehouse.

Copyright © 2024 Jiangsu VISON Logistics Technology Co., Ltd. All Rights Reserved.  Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy