Call Us :8615298359310

Call Us :8615298359310

Introduction:

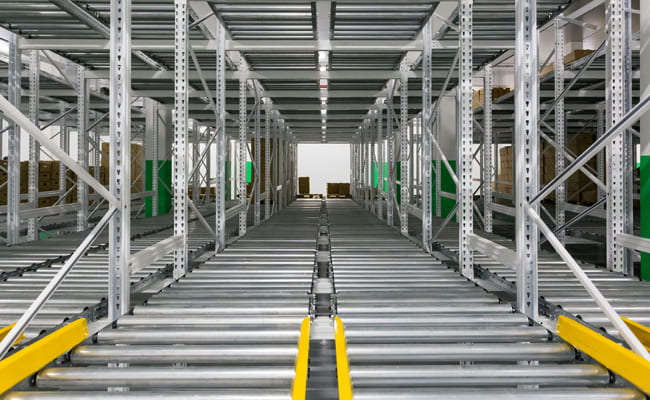

Selecting the appropriate heavy duty racking system for your warehouse is crucial for save your storage space and ensuring operational efficiency. In this article, we'll explore common mistakes to avoid when choosing heavy duty racking solutions. By understanding these pitfalls, warehouse managers can make better decisions.

Underestimating Weight Capacity:

One of the most prevalent mistakes in selecting heavy duty racking is underestimating weight capacity requirements. Before investing in pallet racks, it's essential to accurately assess the load capacity needed to support your inventory. Consider factors such as the weight of each pallet and potential load fluctuations over time. Cantilever racks, known for their ability to accommodate hefty loads, offer versatile storage solutions for bulky items like lumber and steel. However, it's crucial to choose racks with sufficient load-bearing capacity to avoid structural issues and potential safety hazards.

Choosing the Wrong Racking Configuration:

Selecting the wrong type of pallet racking configuration can significantly impact warehouse functionality and storage efficiency. Different industries and product types require customized storage racking solutions. For example, warehouses handling building supplies may benefit from heavy duty cantilever racks, while facilities managing diverse SKUs may opt for selective pallet racking systems. By understanding your inventory profile and operational requirements, you can choose racking configurations that optimize space utilization and facilitate smooth inventory management processes.

Ignoring the Importance of Safety Equipment:

Safety should be a top priority in any warehouse environment, especially when dealing with heavy duty items and industrial equipment. Ignoring the need for safety equipment can lead to accidents, injuries, and costly damage. Guard rail systems, column protectors, and bollards are essential safety features that help mitigate the risk of collisions and protect both personnel and assets. Investing in quality safety equipment not only ensures regulatory compliance but also safeguards your warehouse against potential liabilities and downtime due to accidents.

Opting for In-House Installation:

Attempting to install heavy duty racking systems without professional assistance can lead to installation errors and compromised structural integrity. While some may consider in-house installation as a cost-saving measure, it often results in suboptimal outcomes and safety risks. Professional installation crews equipped with specialized knowledge and tools ensure that racking systems are assembled correctly and meet industry standards for load-bearing capacity and structural stability. By outsourcing installation to experienced professionals, warehouse managers can minimize downtime, mitigate risks, and optimize the performance of their storage infrastructure.

Choosing the right heavy duty racking system is a critical decision that impacts warehouse operations and overall efficiency.

By avoiding common mistakes can optimize storage space, enhance safety standards, and improve productivity. For comprehensive guidance and high-quality racking solutions, warehouse managers can rely on trusted providers like Vijing Logistics Technology to deliver customized solutions tailored to their specific needs and requirements. Consult us now on heavy duty racking solutions that serving your best interest.

Copyright © 2024 Jiangsu VISON Logistics Technology Co., Ltd. All Rights Reserved.  Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy