Call Us :8615298359310

Call Us :8615298359310

Products

Cantilever Steel Racking is a specialized industrial storage racking system especially engineered for handling and storage of long, bulky, or irregularly shaped materials. Unlike traditional pallet racks, cantilever racks offer horizontal space, and its structure makes it easilly accessible for forklift.

1. Lumber and Timber: Commonly stored items include wooden planks, beams, and sheets. Cantilever racking supports the weight and length of these materials, ensuring they remain undamaged and accessible.

2. Metalworks: Pipes, rods, and metal sheets are stored on cantilever racks, which can handle the heavy load and varying sizes of these products.

3. Automotive: This industry stores long vehicle parts, such as exhaust systems, bumpers, and chassis components. Cantilever racking keeps these items organized and prevents damage.

4. Furniture: For storing items like sofas, tables, and mattresses, cantilever racking provides the flexibility needed for different shapes and sizes.

5. Construction: Materials such as drywall, insulation sheets, and rebar are easily stored on cantilever racks, which support their irregular dimensions and heavy weights.

6. Retail: Large retail stores use cantilever racking for displaying oversized products like carpets, rugs, and large pieces of décor.

7. Plumbing: Pipes, tubing, and large fittings are stored efficiently, allowing for easy retrieval and inventory management.

8. Electrical: Spools of wire, conduit, and large cable reels are common items stored on cantilever racks due to their long, bulky nature.

9. Marine: Boat parts, sails, and masts are stored safely and securely on cantilever racks, which can accommodate their unusual shapes and sizes.

10. Textile: Rolls of fabric, carpet, and other large materials are kept organized on these racks, preventing damage and making them easy to access.

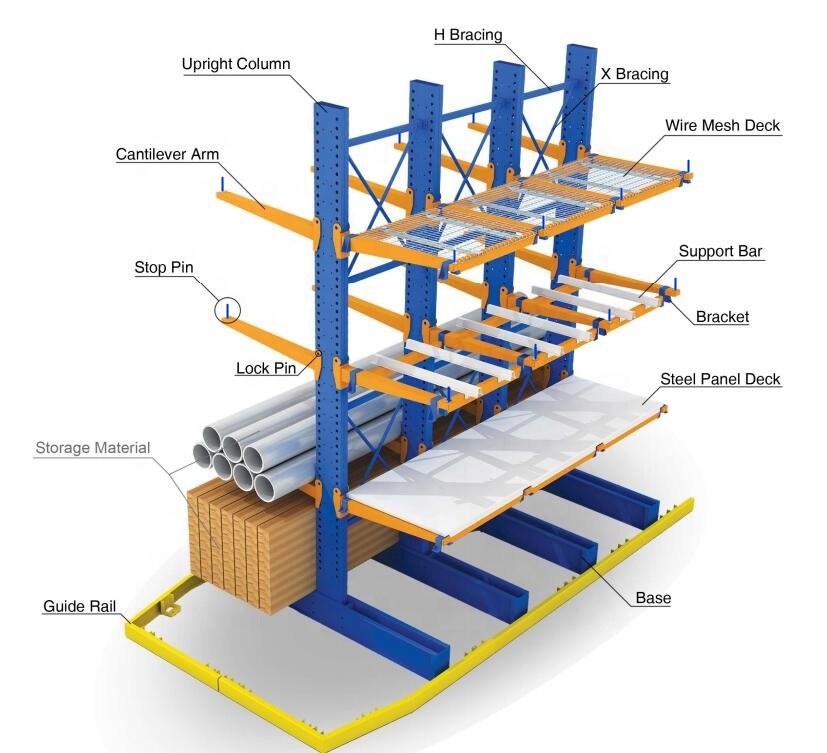

A typical Cantilever Steel Storage Racking system comprises the following components:

|

Upright Profile (mm) |

Upright Height (mm) |

Upright Single Sided Load (kg) |

Upright Double Sided Load (kg) |

Arm Length (mm) |

Arm Load (kg) |

|

Light Duty 150*50 |

1500 |

4000 |

8100 |

300 |

270 |

|

2000 |

3100 |

6300 |

400 |

300 |

|

|

Medium Duty 200*60 |

2500 |

3800 |

7800 |

500 |

440 |

|

3000 |

3300 |

6700 |

600 |

450 |

|

|

3500 |

2900 |

5850 |

700 |

500 |

|

|

Heavy Duty 300*90 |

4000 |

6500 |

13000 |

800 |

690 |

|

4500 |

5850 |

11800 |

900 |

735 |

|

|

5000 |

5350 |

10750 |

1000 |

960 |

|

|

5500 |

4500 |

9150 |

1200 |

1100 |

|

|

Surface Treatment |

Powder Coating or Galvanized (H-type steel Cantilever racking) |

||||

Copyright © 2024 Jiangsu VISON Logistics Technology Co., Ltd. All Rights Reserved.  Network Supported

Network Supported

Sitemap | Blog | Xml | Privacy Policy