Pallet Rack That You Can Run Stuff Through the Middle

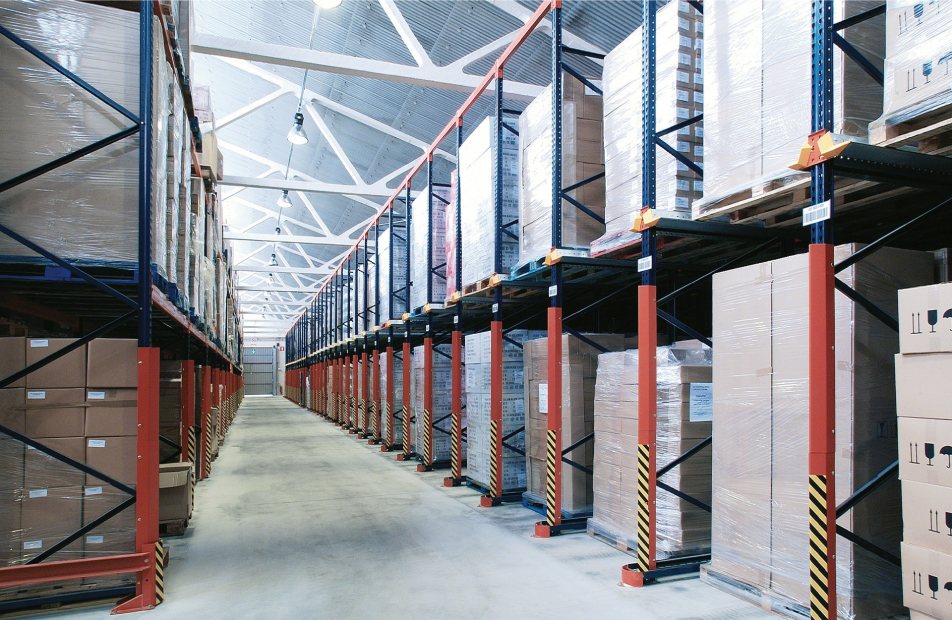

Pallet racking systems play a crucial role in daily warehouse operations. Certain designs, particularly those that allow products to move through the middle, significantly enhance efficiency by streamlining storage and retrieval.

Understanding Pallet Racking

Pallet racks are structured frameworks designed to store goods on pallets within a warehouse. These systems come in various configurations, each tailored to meet specific storage and retrieval needs. The right solution can improve workflow, maximize space, and optimize inventory management.

Pallet Racks with Throughput Capabilities

Some pallet racking systems are designed to allow products to move seamlessly through the system, making retrieval faster and more efficient. This throughput capability minimizes the time spent picking and sorting, leading to a smoother operation and improved overall productivity.

Types of Pallet Racking That Support Throughput

1. Drive-In Racking

Drive-in racking features a compact, high-density design that allows forklifts to enter the structure for loading and unloading. By maximizing vertical storage and reducing aisle space, this system is ideal for warehouses looking to store large quantities of similar products efficiently.

2. Pallet Flow Racking

Pallet flow racking uses gravity-driven rollers to move pallets from the loading side to the picking side. This system follows a First In, First Out (FIFO) approach, ensuring that older stock is used before newer stock. It’s particularly useful for perishable goods and high-turnover inventory, minimizing handling time and improving order accuracy.

3. Push Back Racking

Push back racking operates on inclined rails, where newly loaded pallets push existing ones further back. This system allows for high-density storage while maintaining direct access to multiple pallets within the same lane. It’s a versatile solution for warehouses that handle a variety of inventory types.

Key Benefits of High-Throughput Pallet Racks

- Faster Order Fulfillment: A well-structured racking system eliminates unnecessary search time, keeping orders moving like a Formula 1 pit stop—quick, precise, and efficient.

- Smarter Inventory Management: With products flowing systematically, inventory remains well-organized and easy to track. Think of it as running a well-planned city grid rather than navigating chaotic backstreets.

- Maximized Space Utilization: Instead of expanding outward, warehouses can optimize vertical storage, similar to how ancient civilizations built upward to maximize space. This allows businesses to scale efficiently without costly relocations.

Factors to Consider When Choosing a Racking System

- Warehouse Layout & Space Constraints: The physical dimensions and flow of goods dictate the best racking setup.

- Inventory Type & Turnover Rate: High-turnover products may benefit from FIFO systems like pallet flow racking, while low-turnover items may be better suited for drive-in racking.

- Safety & Compliance: Ensuring that the chosen racking system meets safety regulations is critical for protecting workers and maintaining operational integrity.

Implementing a Throughput Racking System

- Needs Assessment: Identify inefficiencies in the current inventory management process.

- Design & Planning: Develop a racking layout that maximizes space while enhancing workflow.

- Installation: Ensure professional assembly and anchoring for safety and long-term durability.

- Staff Training: Educate employees on proper loading, unloading, and handling techniques.

- Ongoing Safety Measures: Conduct regular inspections and maintenance to uphold safety standards and prevent potential hazards.

Take Efficiency to the Next Level with Automation

To overcome operational plateaus, integrating automated storage and retrieval systems (ASRS) can further streamline order fulfillment and inventory tracking.

Schedule a consultation with Vison today for a comprehensive warehouse efficiency review and expert recommendations tailored to your needs.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information