How to Calculate the Load Capacity of Racking

Table of Contents

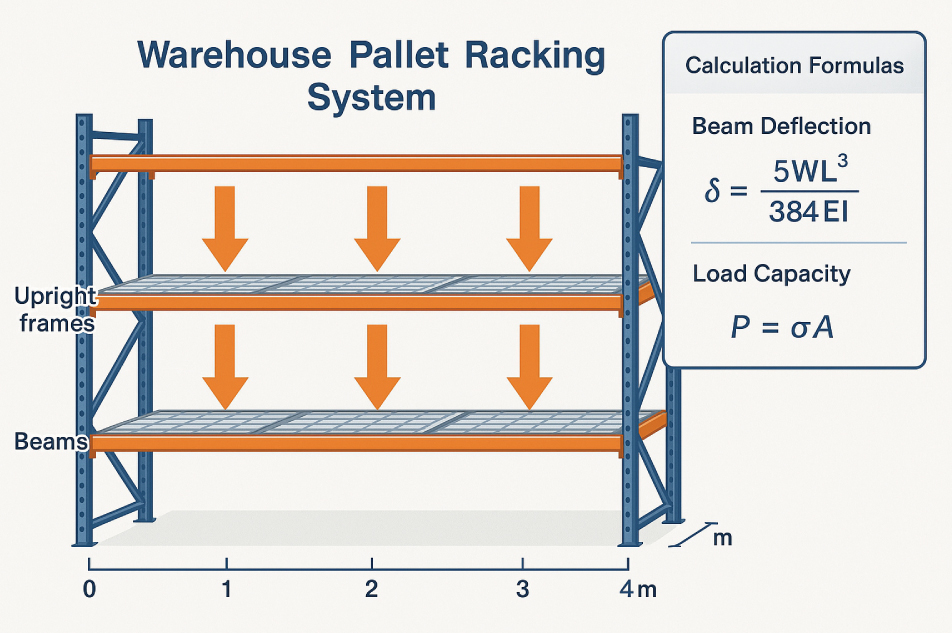

1. Calculating Upright Capacity

The upright frames support the entire rack system’s weight. They absorb dead loads (static weight of the rack itself) and live loads (fluctuating weight of stored inventory).

Key Factors:

- Frame dimensions: height, depth, and column width.

- Material type: cold-formed or hot-rolled steel.

- Manufacturer specifications: load ratings for different frame sizes.

2. Calculating Beam Capacity

Beam strength depends on length and depth, as gravitational forces impact compression and tension distribution.

Load Rating Examples:

| Beam Length | Beam Depth | Load Capacity per Pair |

|---|---|---|

| 96” | 3.5” | 4,044 lbs |

| 96” | 4.3” | 6,111 lbs |

| 144” | 6” | 7,820 lbs |

3. Rating Bowing or Deflection of Pallet Rack Beams

Beams are designed to bow slightly under weight. Deflection is normal but must remain within safety tolerances.

Safety Warning:

Excessive beam deflection can indicate overloading and compromise structural integrity.

4. Calculating Deck Capacity

Decks stabilize pallet loads, ensuring uniform weight distribution across beams.

Load Types:

- Uniform loads: Even weight distribution across the deck.

- Point loads: Concentrated weight in specific areas (e.g., pallet skids).

How Much Can a Pallet Rack Hold?

The total weight capacity of a racking system depends on all components working together. It’s crucial to consult an expert to ensure safety and efficiency.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information